- Product

Industrial Touch Panel

PD series embedded industrial touch panel

15.6-Inch Industrial Touch Panel

PD-881518.5 "Industrial Touch Panel

PD-881823.8-Inch Industrial Touch Panel

PD-882332-Inch Industrial Touch Panel

PD-8832PDS series upper cantilever industrial touch panel

PDX series lower cantilever industrial touch panel

Long Distance Display Solution

PD-Link remote transmission solution

PD-Link remote transmission solutionSPD series industrial touch panel

15 -Inch Industrial touch panel

SPD-150018.5-Inch Industrial touch panel

SPD-190021.5-Inch Industrial touch panel

23.8-Inch Industrial touch panel

Industrial Tablet Computer

TPC Series Tablets

15.6-Inch Industrial Tablet

TPC-561518.5-Inch Industrial Tablet

TPC-561821.5-Inch Industrial Tablet

TPC-562123.8-Inch Industrial Tablet

TPC-562327-Inch Industrial Tablet

TPC-562732 -Inch Industrial Tablet

TPC-5632PPC Series Tablets

15.6-Inch Industrial Tablet

PPC-761518.5-Inch Industrial Tablet

PPC-761821.5-Inch Industrial Tablet

PPC-762123.8-Inch Industrial Tablet

PPC-762327-Inch Industrial Tablet

PPC-762732-Inch Industrial Tablet

PPC-7632HPC Series Tablets

15.6-Inch Industrial Tablet

HPC-961518.5-Inch Industrial Tablet

HPC-961821.5-Inch Industrial Tablet

HPC-962123.8-Inch Industrial Tablet

HPC-962327-Inch Industrial Tablet

HPC-962732-Inch Industrial Table

HPC-9632Industrial Computers

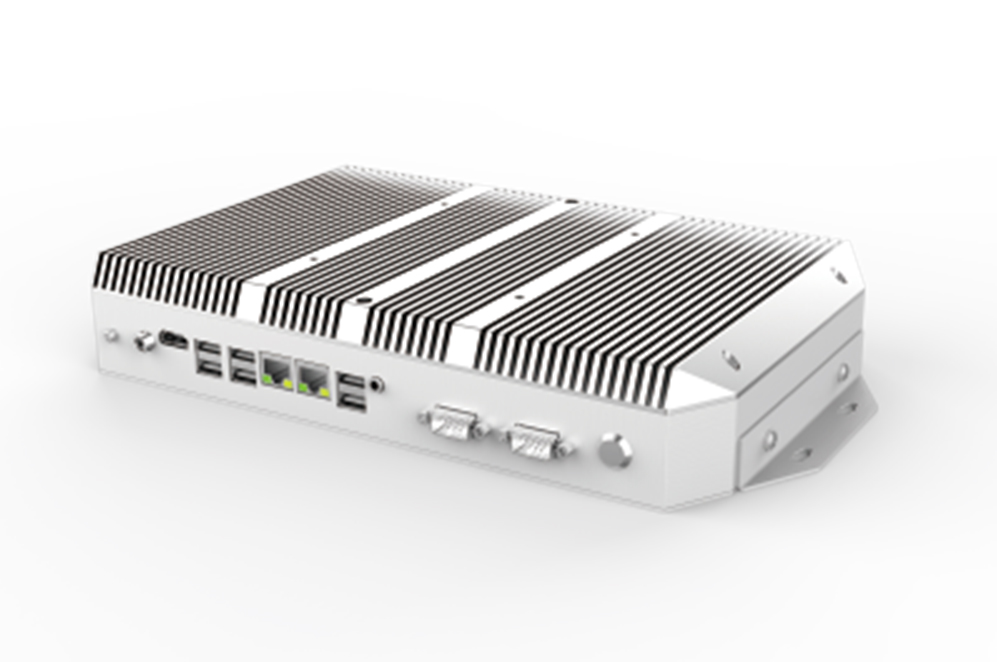

EPC Series Industrial Computer

EPC-16 series industrial computers

EPC-1662Other attachments

HDMI to DVI cable

L-HDMI/DVI-25 L-HDMI/DVI-20 L-HDMI/DVI-15 L-HDMI/DVI-10 L-HDMI/DVI-5 L-HDMI/DVI-3 L-HDMI/DVI-2

- ODM Customization

- Solution

- Technical Support

- About Shangcon

About Shangcon

About Us

Development Course

Quality Assurance

Corporate Culture

Honor and Qualification

Human Resources

News

Product Dynamics

Market Activity

Enterprise News

Business Partner

Client

Supplier

Contact Shangcon

Contact Shangcon